Industrial liquid filling machines are common pieces of machinery that contribute greatly to the production line in the beverage industry. From water and juices to wines and beer, these filling machines can be used for several types of bottled drinks. With its multiple features, they are able to cut costs effectively. Here are 6 advantages that these machines can do for your business.

6 Benefits of Liquid Filling Machines in Bottling Assembly Lines

1. Consistency

Filling containers by hand can lead to inconsistencies when it comes to the amount of product that goes inside. When it comes to bottling, the amount must be precise as the liquid should not be filled to the brim when items are shipped. Measuring instruments may help, though utilizing them will slow down production.

Liquid filling machines can ensure that every bottle is filled with the same amount of product with minimal to no error. They work in a cycle where every product is dispensed precisely based on volume, weight, level, and other input measurements.

2. Increased Production Speed

Filling machines have the capacity to bottle several containers more compared to hand filling production. The speed can depend on the fill heads of the machine and the viscosity of the liquid. On average, a machine with sixteen fill heads can reach speeds of 120 bottles per minute, which can finish thousands of bottles each day.

3. Simple Operating Systems

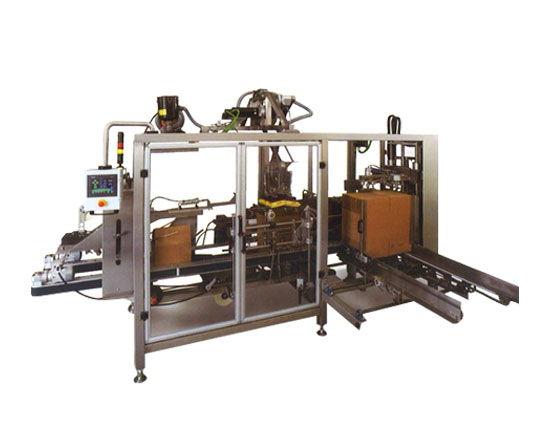

Industrial liquid fillers may seem difficult to operate at first glance, but they come with operating systems that can be easily learned over time. Some bottling machines often only require simple adjustments to change one bottle to another. Other models such as those from Italian manufacturer Matrix are equipped with rotative fillers for simpler and automatic operation. Filling machines have input settings such as indexing times, fill times, and pump speeds.

4. Long Term Use

Industrial filling machines are built to last for longer productions without wearing out. This ensures that you can keep your business running for a longer time. With proper monthly maintenance checks and a few workers alongside the process, you can save on daily expenses on time and energy.

5. Filling Versatility

Filling machines don’t just bottle the same kind of product in the same type of container. When settings are adjusted, these bottling machines can fill any kind of product in any specific measurement. These machines are able to fill both thick and thin liquids, which benefits businesses with multiple lines of production looking for this industrial versatility feature.

6. Scalable

When production requires heavier assistance as the business grows, bottle filling machines can be upgraded without replacing the machine. Depending on the model, most industrial filling machines start with four to six filling heads. This can be added over time. Some models will have a maximum of sixteen fill heads.

Investing in machines for your business may be costly at the start. However, you will receive a return of investments once production begins to pick up. So if you can project the growth of your business, making the step to purchase this equipment is one step closer to greater success.

Also Read: A Startup’s Guide: How to Acquire the Right Packaging Machine

For an effective assembly line, you have to ensure you get high-quality equipment in order to ensure long term use and efficiency. Matrix is an Italian manufacturer of one of the best models for carbonated and non-carbonated bottling machines. Luckily, Elixir Industrial Equipment is a trusted supplier of these filling machines in the Philippines.

Complete with post-sales services such as training, installation, and routine maintenance, this industrial equipment supplier will assist you throughout the entire purchasing process. Contact us to schedule a demo or avail of our items!

Found this helpful? Visit our blog for similar informative content.