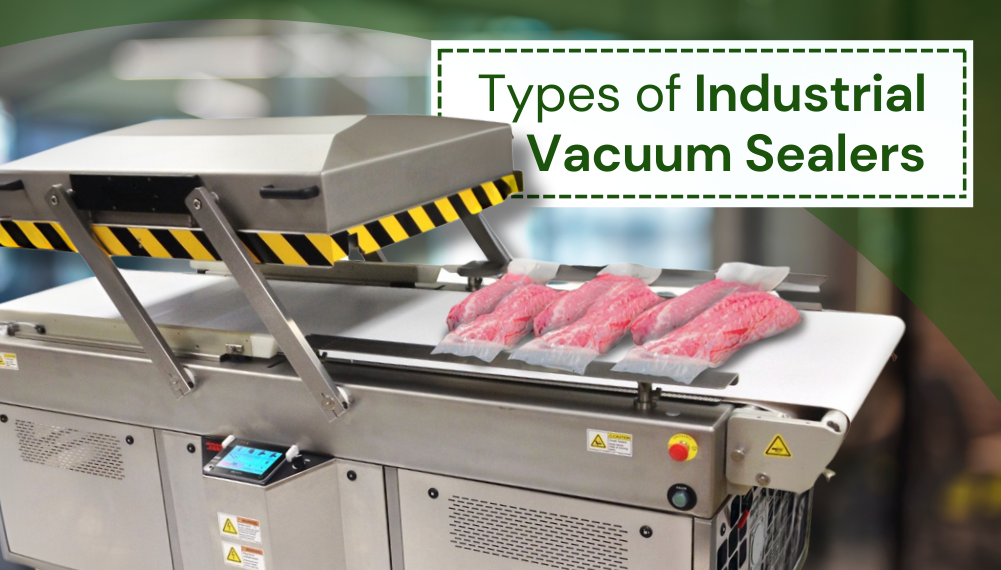

Industrial vacuum sealers are used in various applications. They are essential in protecting and preserving products through the removal of oxygen from packages. These sealers are commonly used in food, electronics, pharmaceuticals, and automotive industries.

As with other industrial machines, industrial vacuum sealers also come in different types to address varying packaging needs and conditions. This article shares some useful information to help you learn more about industrial vacuum sealers.

Different Types of Industrial Vacuum Sealers

1. Chamber Vacuum Sealer

This is common in many industries such as food processing, electronics, and pharmaceuticals. It uses a chamber to seal bags and remove air entirely through one process.

Applications:

- High-volume operations

- Liquid products

- Powders

- Fragile goods

2. Double-Chamber Vacuum Sealers

As the name suggests, these industrial vacuum sealers use two chambers for improved efficiency and reduced downtime. These chambers allow product sealing and preparation for cutting to be done simultaneously. They are most suited for food packaging, pharmaceuticals, and logistics industry.

Applications:

- High-speed, high-volume packaging needs.

3. Nozzle Vacuum Sealers

Also known as External Vacuum Sealers, these industrial machines use a nozzle to remove air directly from the bag without using a chamber. It is ideal for larger items and are commonly used in Manufacturing, Electronics, and Automotive industries.

Applications:

- Industrial parts packaging

- Oversized items packaging

- Non-standard packaging

4. Belt Vacuum Sealers

Also known as conveyor vacuum sealers, these are fully automated sealing machines with a belt used for item transport. Ideal for industries that operate continuously at high-speed such as food and beverage, pharmaceuticals, and electronics.

Applications:

- High-volume production

- Automated production lines.

5. Vertical Vacuum Sealers

Does your operations involve packaging of liquids? Vertical vacuum sealers are what you need. These industrial vacuum sealers are designed for packaging that must be kept upright during sealing. These are most appropriate for food and chemical packaging, as well as medical supplies packaging.

Applications:

- Liquids

- Powders

- Soups and sauces

6. Automatic Vacuum Sealers

If you are into full automation, you’d want automatic vacuum sealers to be integrated into your production line. They can seal packages without human intervention using sensors to initiate the vacuum and sealing process. These machines are perfect for food and beverage production, and for the manufacturing of pharmaceutical and industrial supplies.

Applications:

- Consistent packaging

- High-volume packaging

7. Skin Packaging Vacuum Sealers

This type of industrial vacuum sealer is preferred for its vacuum-tight seal. It uses a film that molds closely to the product for tamper proofing and helps preserve product freshness. Skin packaging vacuum sealer are preferred for the packaging of fresh foods and electronics.

8. Portable Vacuum Sealers

If you have a small and low-volume facility, portable vacuum sealers are the right choice. They are compact and portable and suited for occasional use.

APPLICATIONS:

- Mobile operations

- Small packaging

ALSO READ: 8 Types of Industrial Inks and their Applications

You need the right equipment that can impact operational efficiency, reliability, and overall output. Choose the right industrial vacuum sealer that can help you achieve your goals.

Need help in finding the right industrial equipment for your facility? Talk to us. Elixir has a wide range of machines from CIJ printers to QR coders and vacuum sealers. Let us help you fill your business requirements.