The frozen goods industry is one of the biggest industries that produce hundreds of thousands of products each day. With the food industry being almost half of the country’s output in the manufacturing sector, it is no secret that the printing and coding demands of this sector is at a high standard.

Frozen foods are produced in large quantities daily, which means they will need printing and coding machines that operate quickly and consistently. Durability is also required to ensure long term use. These standards can be successfully met with the following 3 printers and coders.

3 Most Efficient Printers and Coders for the Frozen Goods Industry

1. Linx CIJ Printers

Continuous Inkjet Printers are incredibly versatile, making them suitable for any industry including the frozen goods sector. With speed and consistent output, CIJs continue to be the choice of coder for the food industry. When searching for printers that are known to be reliable, efficient, and are at a low cost of ownership, Linx is a globally known brand that meets these requirements.

With all the features in the Linx 8900 series, the Linx 8940 is known for its high efficiency. Its IP65 rating and impressive printing speeds as one of the highest among its peers, this printer was made to handle the most challenging tasks there is. It also comes with a self-servicing module, which reduces downtime. So if you want production lines to move at a speedy rate, the Linx 8940 is the coding solution that will best suit your standards.

2. Evolabel Thermal Printers

More often than not, frozen good products opt for a ‘print and apply’ process for product labeling. Evolabel completes this task effortlessly, making this tedious task much more simple. This brand is known for its user-friendly functionality, saving time and effort for manufacturers. The following models are the most suitable for the food industry.

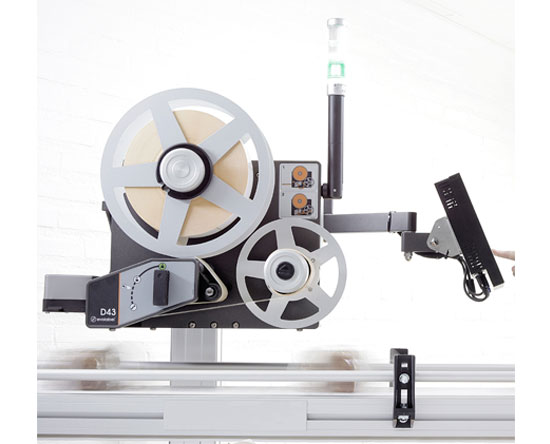

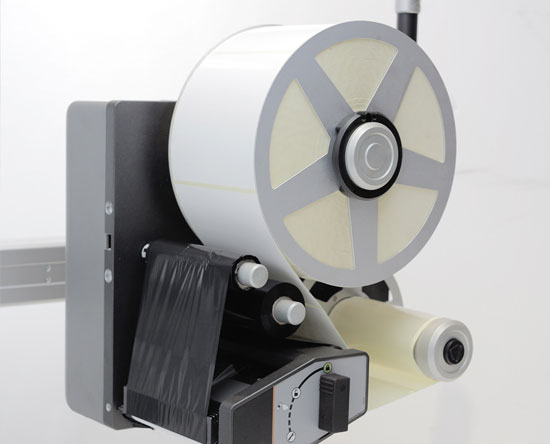

• Evolabel D43 Direct Thermal Printer

Direct thermal technology or “DT” is most often used in the food industry, which the Evolabel D43 offers. It is most ideal for integration in production lines or packaging lines. This machine guarantees almost no fault with a centralized label path and automatic rewind of each label, making 100 percent of the label size printable. This user-friendly feature also makes it much simpler to change between different label widths.

• Evolabel T63 Thermal Transfer Printer

Frozen goods are shipped in bulk, which means they would also require pallet and box labeling. Thermal transfer technology or “TT” is most suitable for this application, most especially with the Evolabel T63 Thermal Transfer Printer. With a print width of 6 inches or 156 mm and a resolution of 300 dpi, this model uses large labels that often carry a lot of data.

These thermal printers are connected to and controlled by Code IT software. This makes it capable of printing labels containing a list of ingredients in up to 15 languages with accuracy when it comes to the positioning of the text and font size.

The Frozen foods manufacturing industry can be quite hectic when facilities don’t work with highly-capable and quality machines that ensure consistent outputs. To avoid unnecessary manufacturing mishaps, it is wise to invest in high-quality equipment from the beginning to ensure industry standards are met in the most efficient way possible.

So when looking for coding solutions that best work with your products, make sure to understand the features you require and prioritize quality in your search for printers.

Also Read: Coding Solutions: Top Choices for the Food and Beverage Industry

Linx and Evolabel are both reputable brands of the manufacturing equipment industry that can best fulfill your business’ coding needs. Luckily, these machines are distributed by Elixir Industrial Equipment, a trusted partner and supplier of world-renowned coding machines in the Philippines. Contact us to find out how you can acquire our top printers straight from the manufacturers.

Visit our blog regularly for more informative content.