Every manufacturer should be knowledgeable about the different codes that need to be printed on their items. Barcode technology was made to make inventory work less difficult, keeping track of sold items automatically and sending it to a database where you can review them. If there are items missing, one can infer that the item was stolen, so in turn, it can help you assess whether or not there is a need to improve security.

But as the years progressed, standard one dimensional (1D) barcodes were no longer the only code that manufacturers can use. Two dimensional (2D) codes such as the QR code was introduced and was then utilized by several industries. So as a manufacturer of goods, it is important to know what makes these two different and what applications can be taken from it for your business. Take a look at everything there is to know about these codes.

QR Code vs. Barcode: Spot Their Differences

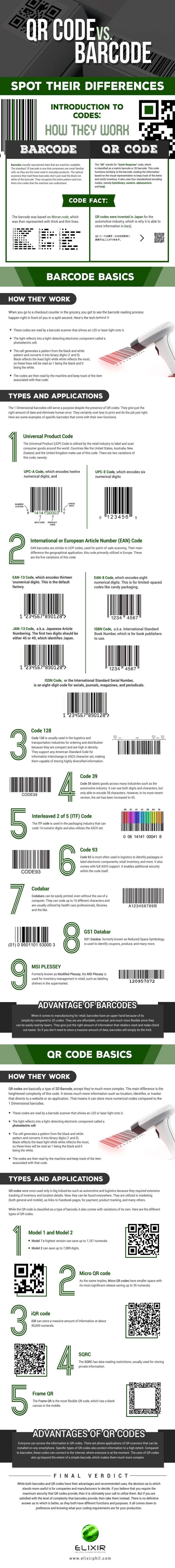

Introduction to Codes: How They Work

• Barcode

Barcodes visually represented data that are machine-readable. The standard 1D barcode is one that consumers are most familiar with, as they are the most used in everyday products. The optical scanners that read these barcodes don’t just read the black nor white of the barcode. They recognize the entire pattern and turn them into codes that the machine can understand.

Code Fact: The barcode was based on Morse code, which was then represented with thick and thin lines.

• QR Code

The “QR” stands for “Quick Response” code, which is classified as a matrix barcode or 2D barcode. This code functions similarly to the barcode, reading the information based on the visual representation to keep track of the items and notify inventory. It also uses four standardized encoding modes, namely byte/binary, numeric, alphanumeric, and kanji.

Code Fact: QR codes were invented in Japan for the automotive industry, which is why it is able to store information in kanji.

Barcode Basics

How They Work

When you go to a checkout counter in the grocery, you get to see the barcode reading process happen right in front of you in a split second. Here’s the tech behind it:

• These codes are read by a barcode scanner that shines an LED or laser light onto it.

• The light reflects into a light-detecting electronic component called a photoelectric cell.

• The cell generates a pattern from the black and white pattern and converts it into binary digits (1 and 0). Black reflects the least light while white reflects the most, so these lines will be read as 1 being the black and 0 being the white.

• The codes are then read by the machine and keep track of the item associated with that code.

Types and Applications

The 1 Dimensional barcodes still serve a purpose despite the presence of QR codes. They give just the right amount of data and eliminate human error. They certainly cost less to print and do the job just right. Here are some examples of specific barcodes that come with their own functions.

1. Universal Product Code

The Universal Product (UCP) Code is utilized by the retail industry to label and scan consumer goods around the world. Countries like the United States, Australia, New Zealand, and the United Kingdom make use of this code. There are two variations of this code, namely:

• UPC-A Code, which encodes twelve numerical digits; and

• UPC-E Code, which encodes six numerical digits

2. International or European Article Number (EAN) Code

EAN barcodes are similar to UCP codes, used for point-of-sale scanning. Their main difference the geographical application, this code primarily utilized in Europe. These are the five variations of this code:

• EAN-13 Code, which encodes thirteen numerical digits. This is the default factory.

• EAN-8 Code, which encodes eight numerical digits. This is for limited-spaced codes like candy packaging.

• JAN-13 Code, a.k.a. Japanese Article Numbering. The first two digits should be either 45 or 49, which identifies Japan.

• ISBN Code, a.k.a. International Standard Book Number, which is for book publishers to use.

• ISSN Code, or the International Standard Serial Number, is an eight-digit code for serials, journals, magazines, and periodicals.

3. Code 128

Code 128 is usually used in the logistics and transportation industries for ordering and distribution because they are compact and are high in density. They support any American Standard Code for Information Interchange or ASCII character set, making them capable of storing highly diversified information.

4. Code 39

Code 39 labels goods across many industries such as the automotive industry. It can use both digits and characters, but only able to encode 39 characters. However, in its most recent version, the set has been increased to 43.

5. Interleaved 2 of 5 (ITF) Code

The ITF code is used in the packaging industry that can code 14 numeric digits and also utilizes the ASCII set.

6. Code 93

Code 93 is most often used in logistics to identify packages in label electronic components, retail inventory, and more. It also comes with full ASCII support. It enables additional security within the code itself.

7. Codabar

Codabars can be easily printed, even without the use of a computer. They can code up to 16 different characters and are usually utilized by health care professionals, libraries, and the like.

8. GS1 Databar

GS1 Databar, formerly known as Reduced Space Symbology, is used to identify coupons, produce, and many more.

9. MSI PLESSEY

Formerly known as Modified Plessey, the MSI Plessey is used for inventory management in retail, such as labeling shelves in the supermarket.

Advantage of Barcodes

When it comes to manufacturing for retail, barcodes have an upper hand because of its simplicity compared to 2D codes. They are affordable, universal, and much more flexible since they can be easily read by lasers. They give just the right amount of information that retailers need and make check out easier. So if you don’t need to store a massive amount of data, barcodes will simply do the trick.

QR Code Basics

How They Work

QR codes are basically a type of 2D Barcode, except they’re much more complex. The main difference is the heightened complexity of this code. It stores much more information such as location, identifier, or tracker that directs to a website or an application. That means it can store more numerical codes compared to the 1 Dimensional barcodes.

Types and Applications

QR codes were once used only in big industries such as automotive and logistics because they required extensive tracking of inventory and location details. Now, they can be found everywhere. They are utilized in marketing (both general and mobile), as links to Facebook pages, for payment, product tracking, and many others.

While the QR code is classified as a type of barcode, it also comes with variations of its own. Here are the different types of QR codes.

1. Model 1 and Model 2

• Model 1’s highest version can save up to 1,167 numerals.

• Model 2 can save up to 7,089 digits.

2. Micro QR code

• As the name implies, Micro QR codes have smaller space with its most significant release saving up to 35 numerals.

3. iQR code

• iQR can store a massive amount of information at about 40,000 numerals.

4. SQRC

• The SQRC has data reading restrictions, usually used for storing private information.

5. Frame QR

• The Frame QR is the most flexible QR code, which has a blank canvas in the middle.

Advantages of QR Codes

Everyone can access the information in QR codes. There are phone applications of QR scanners that can be installed on any smartphone. Specific types of QR codes also protect information to a high extent. Compared to barcodes, these codes can connect to the internet, where everyone is at the moment. The uses of QR codes also go beyond the extent of a simple barcode, which makes them much more complex.

While both barcodes and QR codes have their advantages and recommended uses, the decision as to which stands more useful is for companies and manufacturers to decide. If you believe that you require the maximum security that QR codes provide, then it is ultimately your call to utilize them. But if you are satisfied with the level of complexity that barcodes provide, then take them instead. There is no definitive answer as to which is better, as they both have different functions and purposes. It all comes down to preference and knowing what your coding requirements are for your production.

Also Read: Why Your Startup Business Should Invest in Linx Coding Equipment

Whichever code you choose to use for your products, you will need high-quality coding solutions. Linx is an excellent manufacturer of top-class industrial printers and coders worldwide, including high-quality QR codes and barcodes in the Philippines. Elixir Industrial Equipment is a trusted supplier of Linx coding solutions with a wide selection of models straight from UK factories. Contact us now to know the equipment and services we can provide for you.

In search of a dependable supplier of QR codes and barcodes in the Philippines? Browse through our product coding machines to know what we offer.