Thinking of investing in a conveyor belt for your assembly line? It’s important to choose a conveyor that best suits the needs of your company. If you want to make an informed purchase, you might want to know the basic types of conveyors and match them with your business applications. The right belt can even help increase profit margin, streamline your assembly line, and contribute to company growth in ways that you might not picture at first. To start you off, here’s a rundown of the 8 basic types of conveyor belts, along with their applications.

8 Basic Types of Conveyor Belts and Their Applications

1. Roller Bed Conveyor Belts

Image Source: New London Engineering

As the name suggests, the surface of this type of conveyor belt is made up of rollers that are selected to match production requirements, such as the weight or required speed of the products that will move along the belt. Shorter conveyor belts that fall under this type can be made up of just two rollers. However, as the distance between the two ends of the belt increases, more will be needed for the belt to function.

A roller bed setup is suitable for when items are loaded onto the belt with gravity. This is because manual loading can cause mechanical shock and damage the rollers. Roller bed conveyor belts are also a good option for transporting items over long distances as they reduce friction, making it easier for products to move along the belt.

APPLICATIONS: You can use these conveyor belts for packing, sorting, assembling, inspecting, and transporting items. Common applications of roller bed conveyor belts include postal sorting offices and airport baggage handling systems.

2. Flat Belt Conveyors

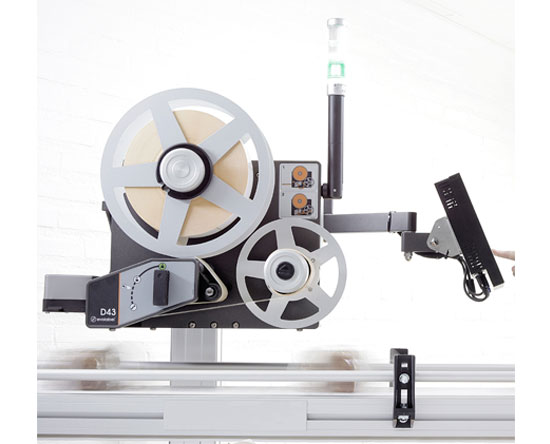

Image Source: Press Room Automation and Feed Fixtures

The flat belt conveyor belt is one of the most prevalent conveyor systems in use today. Flat belts are useful for internal conveyance, i.e. transporting items within a facility. This type of conveyor belt uses a series of powered pulleys to move a continuous flat belt, which can consist either of natural material or synthetic fabric (ex. polyester, nylon). Items are placed on top of the moving belt and carried from one end to the other.

Since its belts can be made of different kinds of materials, this type of conveyor belt is incredibly versatile. Optional features include center drives and nose bars depending on the requirements of a given application.

APPLICATIONS: Flat belt systems are often the conveyor of choice for industrial environments, wash down areas, and slow assembly lines. Fitted with the right belt, it can also convey small, soft, or irregularly shaped items without damaging them.

3. Modular Belt Conveyors

Image Source: Press Room Automation and Feed Fixtures

While flat belt conveyors use a single, continuous loop of material, modular conveyor belt systems use a single loop made of countless interlocked pieces, usually made of hard plastic. These segments can be removed and replaced individually, in contrast to having to discard the entire belt. They’re also easier to wash, as well as more resistant to sharp and abrasive materials. This makes modular belt conveyors simpler to maintain and repair than their flat belt counterparts.

Modular belt conveyors are well-suited to applications that involve travelling around corners. In fact, they can travel straight, go around a corner, and incline and decline using a single belt and the same motor all throughout. Technically, other types of conveyors can also accomplish this feat, but only with much customization and additional costs. Plastic modular belts also allow specific conveyor designs without compromising belt tracking. An example of this is a belt with greater width than length, which provides the support required to handle soft plastic bags, cardboard boxes, and shrink wrapped goods.

APPLICATIONS: This type of conveyor belt can be used to carry food products because it is easy to clean. Spacing between plastic segments are adjustable for applications where fluid should be either drained or retained as it is carried on the conveyor. The segments’ plastic composition also makes this conveyor belt useful for metal detection.

4. Cleated Belt Conveyors

Cleated belt conveyors feature vertical cleats or barriers in their designs. These cleats can keep loose materials secure during inclines and declines, to provide consistent spacing between items, and more. Furthermore, cleats come in different shapes, each with its own application.

• Inverted Capital “T.” This type of cleat stands perpendicular to the belt surface, providing support and flexibility to handle delicate items. It is suited for light-duty jobs, such as transporting small parts, packaged items, and food products.

• Forward-Leaning Capital “L.” The wide base of this cleat makes it more resistant to leverage forces. Some cleats with this shape also have curved faces, which enables them to scoop granules. This type of cleat is designed to carry light- to medium-weight bulk material up steeper inclines.

• Inverted “V.” Cleats with this shape are usually 2 inches or less in height to allow for a troughing effect. They’re best for transporting abrasive, heavy, or large-piece bulk materials, as they can withstand heavy impacts.

• Lugs and Pegs. These kinds of cleats accommodate specific needs. For instance, they can promote run-off of liquids when used to transport washed fruit or vegetables. They’re also a cost-efficient cleat type for items that don’t need to be supported throughout the full belt width, such as rods and cartons. They can even be positioned to selectively move products exceeding a given size or to hold individual products in place.

An offshoot of the cleated belt is the elevator belt. Designed with regularly spaced partitions or scoops, it is designed to carry loose materials up a steep incline.

5. Curved Belt Conveyors

Image Source: Accurate Industrial

This type of belt conveyor uses a curved frame to carry items around corners, make tight transfers, or maximize available floor space. These belts’ curves can go up to 180°. True curved conveyors that do not have any straight runs can only use flat belts, as modular plastic belts require straight runs before and after curves.

APPLICATIONS: Curved belt conveyors are often used in bag handling systems to change items’ conveying direction.

6. Incline/Decline Belt Conveyors

Incline belt conveyors feature a center drive, gear motor, and take-up with a single or double nose. And instead of using a smooth-surfaced belt, this type of conveyor has a rough surface on the belt, ideal for carrying products up or down.

APPLICATIONS: These systems can cross over with cleated belt conveyors to transport products to different elevations while keeping them from falling off the line. Aside from transferring objects between floors, these conveyor belts are also suitable for boosting gravity flow systems.

7. Sanitary and Washdown Conveyors

Image Source: Food Engineering

If you’ve ever observed how donuts are manufactured in their shops, you might have seen this type of conveyor belt in action. Donut shops and other applications in the food and pharmaceutical industries often involve harsh washing and sterilization, in compliance with safety guidelines. Sanitary or washdown conveyors are specially designed to withstand the sanitary procedures for these applications. Conveyors under this type are usually fitted with flat wire belts, which are rugged and easy to clean.

APPLICATIONS: These conveyor belts can carry objects with extreme temperatures straight out of furnaces or freezers. In addition, machines in the food industry, in particular, must survive running through glaze, breading, or hot oil. Because they can securely handle both wet and greasy items, larger washdown conveyors with flat wire belts are also suited for offloading break bulk goods, like oil drums and crates, from ships.

8. Specialty Conveyor Belts

There are several other kinds of conveyors tailored for different applications, although they are not as common as the previous types. Some of these are:

• Fiberglass Conveyor Belts – As the name implies, this type of conveyor belts are made of fiberglass. They are useful for tasks that require extreme temperatures.

• Metal Nub Conveyor Belts – This particular conveyor belt is fitted with metal nubs to better handle complex machines and their parts.

• Narrow-width Conveyor Belts – This type of conveyor belt is the best choice for handling small items.

• Back-lit Conveyor Belts – They come with a light fixture on the belt to aid with quality control.

• Vacuum Conveyor Belts – This particular conveyor belt creates suction to keep light products (sheets of paper, leaflets, etc.) on the line despite inclines and high speeds.

• Magnetic Conveyor Belts – This type of conveyor belt can transport materials that contain iron through equally spaced electromagnets that are placed within the bed of the conveyor.

• Sandwich Belt Conveyors – They use two face-to-face belts to securely carry items at steep inclines or even up a vertical run.

ALSO READ: Cobot Basics: 5 Ways Collaborative Robots Can Improve Your Assembly Line

Keep this list in mind, and you can have a rough idea of what conveyor belt you’ll be looking for. However, it’s highly advisable to consult an expert before finalizing any equipment purchases!

Elixir Industrial Equipment, Inc. is one of the top industrial equipment suppliers in the Philippines. For 25 years and counting, we have provided our clients with cutting-edge industrial equipment as well as professional post-sales service. Aside from providing you with professional advice, we can even offer you the manufacturing solutions you’ve been looking for. If you’re strongly considering installing a conveyor belt along your assembly line, feel free to contact us today!

Looking into using conveyor belts to improve your assembly line? Hayama Industrial Corporation is a trusted name when it comes to the Design, Fabrication, Manufacturing, Rehabilitation, Installation, Commissioning of Packaging Equipment, Support peripherals, and auxiliaries including conveyor belts.

Visit their website today to find out how they can help you with your requirements.